How Turnkey PCB Assembly Helps Startups and Growing Brands Scale Faster

Launching a new electronic product is an exciting milestone, but it also comes with serious challenges. Startups and growing brands often operate with limited budgets, tight timelines, and small teams. Managing complex manufacturing processes under these conditions can slow progress and introduce unnecessary risks. This is why many young and expanding companies are turning to turnkey PCB assembly as a practical manufacturing solution.

Turnkey PCB assembly allows businesses to simplify production, reduce coordination efforts, and focus on product development instead of operational complexity. For startups and scaling brands, this approach can make the difference between a delayed launch and a successful market entry.

The Manufacturing Challenges Faced by Startups

Unlike large corporations, startups usually lack dedicated procurement, quality control, and manufacturing teams. Common challenges include:

- Limited experience with component sourcing

- Difficulty managing multiple vendors

- Unpredictable production costs

- Delays caused by design or sourcing errors

- Limited ability to scale production quickly

These challenges often result in missed deadlines, higher costs, and quality issues. Turnkey PCB assembly addresses these pain points by offering a structured and manageable manufacturing path.

What Makes Turnkey PCB Assembly Startup-Friendly?

Turnkey PCB assembly is designed to reduce complexity. Instead of coordinating with separate suppliers for components, PCB fabrication, assembly, and testing, startups work with a single provider that manages everything.

This approach is particularly helpful for new companies because it removes guesswork from the manufacturing process. Clear communication, defined workflows, and professional oversight allow startups to move forward with confidence.

Faster Prototyping and Product Validation

For startups, speed matters. The ability to quickly test and validate prototypes helps refine product design and attract investors or early customers.

Turnkey PCB assembly supports rapid prototyping by:

- Reviewing designs for manufacturability

- Sourcing components efficiently

- Producing small batches quickly

- Identifying issues early through testing

This fast feedback loop enables startups to improve designs without long delays or excessive costs.

Simplified Component Sourcing for New Businesses

Component sourcing is one of the most difficult aspects of electronics manufacturing, especially for startups. Without established supplier relationships, new businesses risk receiving incorrect or counterfeit parts.

Turnkey PCB assembly providers handle sourcing through trusted supply networks. This ensures that components meet specifications and remain consistent across production runs. For startups, this reliability is critical to building a stable product foundation.

Cost Control and Budget Predictability

Startups must manage budgets carefully. Unexpected costs during manufacturing can disrupt financial planning and delay growth.

Turnkey PCB assembly helps control costs by:

- Providing clear pricing structures

- Reducing logistics expenses

- Minimizing rework and defects

- Streamlining production timelines

With predictable costs, startups can plan launches, pricing, and scaling strategies more effectively.

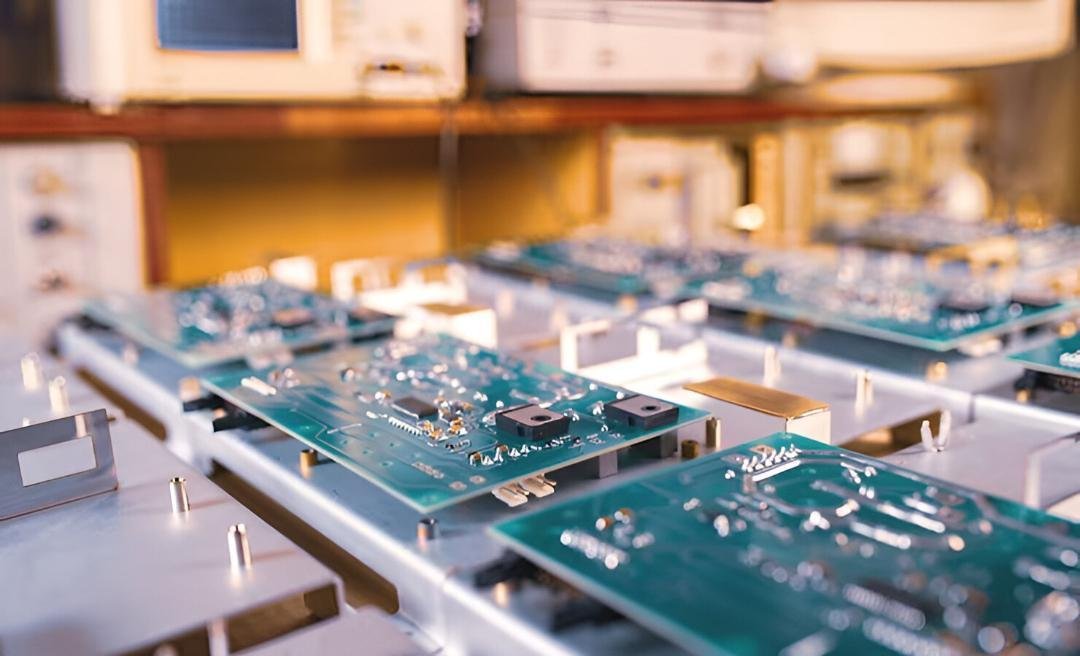

Scaling from Prototype to Production

One of the biggest transitions for startups is moving from prototype to mass production. Many companies struggle at this stage due to inconsistent processes or supplier limitations.

Turnkey PCB assembly supports smooth scaling by maintaining the same production standards across different volumes. Whether producing a small pilot batch or preparing for larger orders, the process remains consistent and controlled.

A reliable provider offering Turnkey PCB Assembly Services allows growing brands to scale production without introducing new risks or delays.

Quality Assurance for Brand Reputation

For startups, early customer feedback can make or break a brand. Product failures or quality issues can damage reputation before the company has a chance to grow.

Turnkey PCB assembly emphasizes quality control throughout the manufacturing process. Regular inspections, testing, and verification ensure that products meet performance expectations before reaching customers.

This focus on quality helps startups build trust and credibility in competitive markets.

Engineering Support for Limited In-House Teams

Most startups do not have large engineering teams dedicated to manufacturing optimization. Turnkey PCB assembly providers often offer engineering support that helps improve design and manufacturability.

This support includes:

- Design reviews

- Layout optimization suggestions

- Identification of potential assembly issues

- Recommendations for cost-effective components

Such guidance helps startups avoid common mistakes and accelerate development.

Supporting Innovation Without Operational Overload

Innovation is the core strength of startups, but operational complexity can distract teams from creative work. Turnkey PCB assembly reduces this burden by handling production details efficiently.

With manufacturing managed externally, internal teams can focus on:

- Product features and performance

- User experience improvements

- Market research and customer feedback

- Business development and partnerships

This balance supports sustainable growth and innovation.

Global Market Readiness

Many startups aim to enter global markets early. However, meeting international quality and compliance standards can be challenging without manufacturing experience.

Turnkey PCB assembly providers follow recognized industry standards, helping startups prepare products for broader market acceptance. This readiness supports expansion into new regions and customer segments.

Companies that rely on Turnkey PCB Assembly Services gain the manufacturing stability needed to compete beyond local markets.

Real-World Benefits for Growing Brands

Growing brands benefit from turnkey PCB assembly in several practical ways:

- Reduced production stress

- Faster launch cycles

- Improved product consistency

- Easier scaling strategies

- Better long-term cost management

These benefits allow companies to focus on growth rather than troubleshooting manufacturing issues.

Manufacturing Expertise Behind the Process

Manufacturers like globalwellpcba.com specialize in providing end-to-end PCB solutions tailored to the needs of startups and expanding businesses. Their structured workflows and technical experience help new brands transition smoothly from concept to production.

Final Thoughts

For startups and growing brands, manufacturing efficiency is just as important as product innovation. Turnkey PCB assembly offers a reliable pathway to reduce complexity, control costs, and scale production with confidence.

By combining sourcing, fabrication, assembly, and testing into a single coordinated process, turnkey PCB assembly empowers new businesses to bring products to market faster and more reliably.